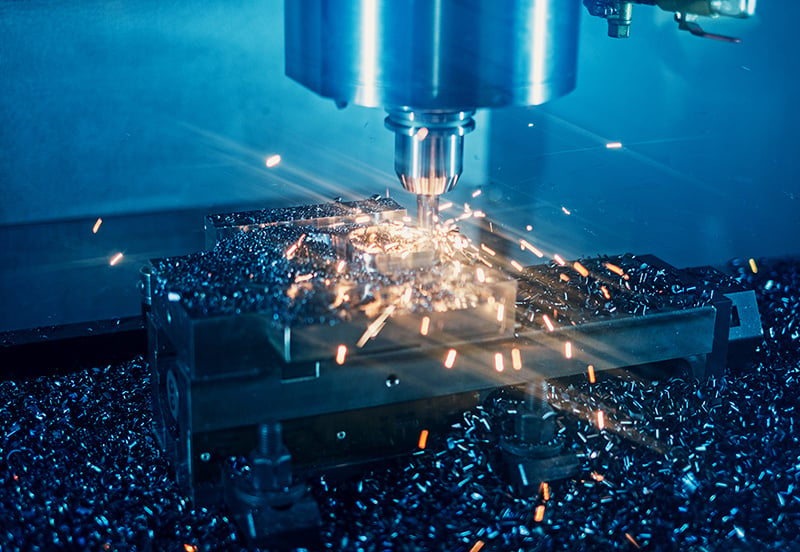

Machining

Interfuse Manufacturing brings a history of 40+ years of machining experience and technology to ReNEW Manufacturing Solutions.

We offer ReNEW customers complete CNC machining operations to provide a final manufactured component to our customers. Not only are we able to complete the entire machining process, our vast experience allows us to troubleshoot difficult issues and improve the overall fit of final components.

We use state-of-the art CAD-CAM technology in UNIGRAPHICS to achieve complex contour machining. All ReNEW companies also offer the capability to translate all standard engineering file formats and build quality parts to exact customer specifications. Before proceeding to full production, ReNEW shops always monitor and track all cutter paths to verify accuracy.

Our high-speed, high-performance machining capabilities enable us to combine numerous operations for greater efficiency. With CNC machinery ideally suited for prototype, short run, and production quantities from a few pieces to several thousand, we're an end-to-end partner. Even when Interfuse does not currently house the ideal machinery for your project, ReNEW Manufacturing Solutions is always eager to invest in new equipment that expands our capabilities and best serves you, our valued customers.

We have a strong history in machining molds for brick refractory, glass industries, and, more recently, machining welded fabrications and fabricated parts for multiple equipment industries. Interfuse has the capability to rotary, surface, ID, and OD grind specialty metals, such as tool steel and carbide, using advanced ceramics and armored diamond abrasives.

We also provide heat treating services, including atmosphere controlled furnaces, to provide scale-free parts, which are highly desirable on intricate die parts without any secondary operations. We are able to through-harden a range of tool steels, as well as oil-quenched steels. We provide thermal stress relieving, vibratory stress relieving, and annealing. All heat treating services are tracked with direct read charts and are inspected with appropriate Brinell and Rockwell testers.

Finally, Interfuse Manufacturing also offers ReNEW customers cryogenic treatment of materials in conjunction with heat treating. This process will extend the life of a treated part up to three times longer than that of an untreated part and provide more stable and wear-resistant parts.

With the ability to engineer, fabricate, weld, and machine, what starts in our facility as raw metal, has the ability to ship as a complete manufactured component.

See our Welding and Fabricating capabilities.

CNC Equipment

- MAG HMC 1250 – Dual Pallet Machining Center (1250 mm Pallet)

- Johnford DMC 3000X1500 Double Column Machine (table size 125.9 X 51.1")

- (3) Kingsbury VMC 600 Vertical Machining Center (table size 50 X 60")

- Johnford SV-45 Vertical Machining Center (table size 20 X 48")

- Giddings & Lewis Lathe (15 X 75")

- Doosan Lynx 300 Lathe

- OKUMA Vertical Machining Center (20 X 40")

- Makino A71 Horizontal Machining Center with Pallet Changer (500 mm Pallet)

- KIA Horizontal Machining Center with Pallet Changer (800 mm Pallet)

- (3) Harding Talent S/45 Lathes (1) with 144" Bar Feeder Up to 1.5 Diameter

- Mitsubishi Wire EDM

Grinding Equipment

- Mattison Rotary Grinder (table size 54" dia.)

- Blanchard Rotary Grinder (table size 42" dia.)

- Mattison Surface Grinder (table size 24 X 60")

- Mattison Surface Grinder (table size 18 X 48")

- Elliot Surface Grinder (table size 9 X 21")

- Harig Surface Grinder (table size 6 X 18")

- Boyer Schultz Surface Grinder (table size 6 X 14")

- Heald Internal Grinder

- Schaudt External Grinder

Manual Milling/Turning Equipment

- (5) Bridgeport Series I

- Famot Lathe (10 X 32")

- Clausing Lathe (21 X 96")